In the intricate workings of modern vehicles, there lies a small yet significant player—often unnoticed yet indispensable. The O2 sensor, or oxygen sensor, is the unsung hero of an engine’s performance, monitoring the balance between oxygen and fuel.

It ensures that combustion, that most fundamental process that powers a vehicle, happens efficiently, reducing waste and harmful emissions.

Much like the celestial bodies in the vast expanse of space, the O2 sensor’s voltage signals, though small, hold the key to understanding the delicate balance that governs engine health, fuel efficiency, and environmental responsibility.

The Role of the O2 Sensor: Monitoring the Breath of the Engine

Embedded in the exhaust system of a vehicle, the O2 sensor serves as a sentinel, measuring the oxygen levels in the exhaust gases.

It compares the oxygen present in the exhaust to the oxygen in the surrounding air, relaying critical information to the engine control unit (ECU). Based on this data, the ECU adjusts the air-fuel ratio, ensuring the engine burns fuel efficiently and reduces harmful emissions.

In essence, the O2 sensor monitors the ‘breath’ of the engine, providing real-time feedback to ensure that the vehicle runs smoothly.

Like an astronomer’s telescope capturing distant stars, the O2 sensor’s data offers us a window into the internal workings of the engine, reflecting the harmony—or discord—of combustion.

Oxygen Sensor Voltage Ranges: A Window into Engine Performance

The O2 sensor’s voltage output is not just a series of random numbers; it’s a window into the efficiency of combustion. This voltage varies depending on the amount of oxygen in the exhaust gases, and it provides valuable insight into the performance of the engine.

Understanding these voltage ranges can help diagnose issues, improve performance, and reduce emissions.

-

Low Voltage (0.1V - 0.3V): When the voltage falls within this range, it indicates that the air-fuel mixture is lean—meaning there’s too much oxygen in the exhaust. This scenario typically suggests inefficient combustion, where the engine isn’t burning fuel optimally.The engine may be underperforming, producing higher emissions and wasting fuel. Such a state often occurs during idling or light-load driving conditions.

-

Mid-Range Voltage (0.4V - 0.6V): This is the sweet spot for the engine. At these voltage levels, the air-fuel ratio is balanced, and combustion is happening at its most efficient. The engine runs smoothly, fuel consumption is optimized, and emissions are minimized. This voltage range is the goal of a well-maintained and properly tuned engine, where everything is working in harmony.

-

High Voltage (0.7V - 1.0V): A high voltage reading indicates a rich fuel mixture—meaning there’s less oxygen in the exhaust and more fuel is being burned than necessary. While this may be desirable during high-demand situations, like rapid acceleration or heavy load driving, it can lead to inefficient fuel usage and increased emissions when the engine is not under such stress.

The Warnings of Malfunction: When the Sensor Fails

Like a dying star whose light fades from the sky, a malfunctioning O2 sensor no longer provides reliable data. A faulty sensor may send incorrect voltage signals, which in turn mislead the engine control unit into adjusting the air-fuel mixture improperly.

This can result in poor fuel efficiency, engine hesitation, and a significant increase in harmful exhaust emissions.

When the O2 sensor fails, it’s essential to address the issue promptly. Ignoring a malfunctioning sensor can lead to long-term engine damage, reduced performance, and a heavier environmental footprint.

Fortunately, modern diagnostic tools can help identify these failures before they become major issues.

O2 Sensor Troubleshooting: Diagnosing Issues with Modern Tools

Just as astronomers use powerful telescopes to peer into the distant reaches of the cosmos, modern vehicle diagnostics tools help us peer into the engine’s performance and pinpoint problems with the O2 sensor. Advanced scanners allow us to read live sensor data, track voltage readings, and diagnose problems in real-time.

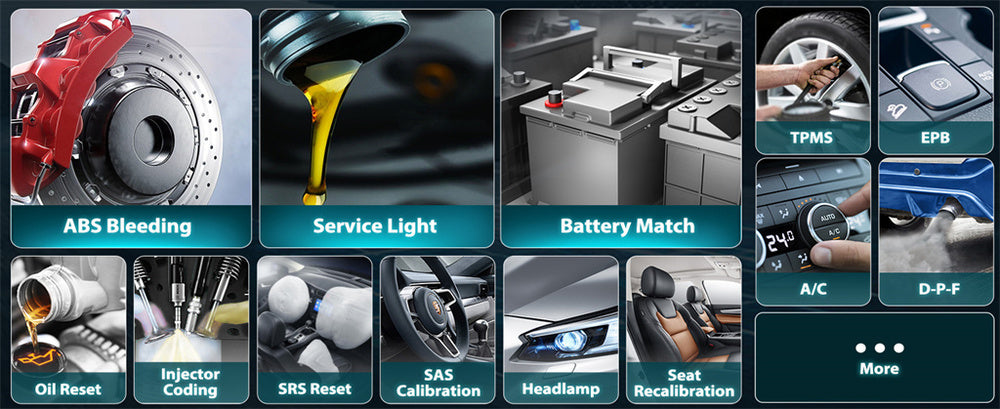

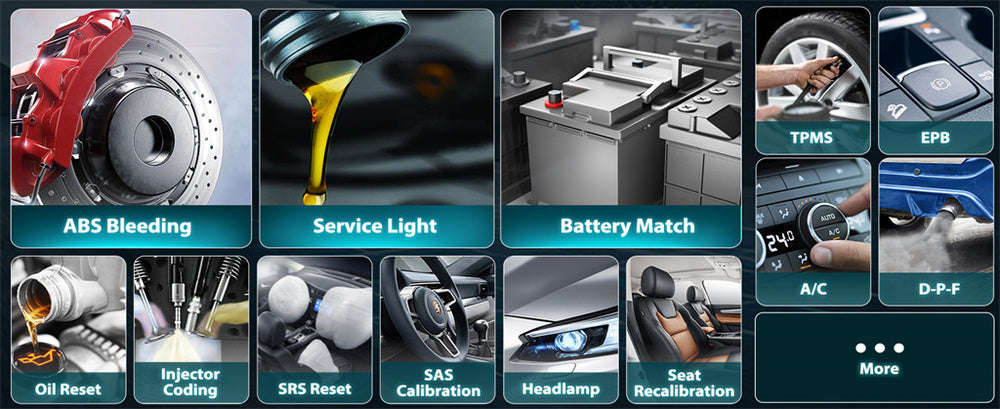

One such tool is the Foxwell NT809TS, an advanced OBD2 scanner designed for comprehensive diagnostics. With its ability to read live data from the O2 sensor, the NT809TS can provide real-time voltage readings, allowing you to observe how the sensor is performing in various driving conditions.

This tool can help you pinpoint issues such as a malfunctioning O2 sensor, poor combustion, or improper air-fuel mixtures, giving you a clear understanding of your vehicle’s health.

Key Benefits of the Foxwell NT809TS for O2 Sensor Diagnosis

- Live Data Monitoring: The NT809TS allows you to monitor real-time data from the O2 sensor, enabling you to see its voltage output during various driving conditions.

- Error Code Reading: If the O2 sensor is malfunctioning, the NT809TS can scan and display the error codes, offering insight into what is going wrong.

- Enhanced Diagnostics: This tool can also scan and diagnose other components of the vehicle, ensuring that the entire system is running efficiently, and no issues are overlooked.

By using diagnostic tools like the Foxwell NT809TS, you can proactively identify problems with the O2 sensor and other critical systems, avoiding costly repairs and ensuring your vehicle operates efficiently.

From the Microcosm of the Engine to the Macrocosm of the Environment

Carl Sagan often spoke about the interconnectedness of all things, from the tiniest particles to the farthest stars. The O2 sensor, in its quiet role, reflects this connection. It not only helps to optimize the engine’s performance but also plays a significant role in reducing the environmental impact of the vehicle.

By ensuring that the engine burns fuel efficiently, the O2 sensor reduces harmful emissions and conserves fuel, making it a key player in both vehicle performance and environmental sustainability.

Every small adjustment made by the O2 sensor and every piece of data it provides contributes to a larger story—a story about how technology, science, and nature are inextricably linked. Much like the stars above, the O2 sensor helps us understand the delicate balance that sustains life, both within the engine and on the planet.

Conclusion

The O2 sensor, though small, is a cornerstone of modern vehicle performance. It provides crucial data that helps maintain the balance between air, fuel, and combustion, ensuring that the engine runs smoothly and efficiently.

By understanding the voltage ranges and how they correlate with engine performance, we can troubleshoot issues before they become serious, optimize fuel efficiency, and reduce emissions.

In the same way that Sagan’s work illuminated the vast, interconnected universe, the O2 sensor reveals the intricate balance within our vehicles, reminding us that every small detail matters in the greater ecological picture.

With tools like the Foxwell NT809TS, we can ensure that the vehicle’s engine remains in harmony with the world around it, both in terms of performance and environmental impact.

FAQs

How to read O2 sensor voltage?

Use an OBD2 scanner or diagnostic tool to monitor the live data stream from the O2 sensor. The voltage typically fluctuates between 0.1V and 1.0V depending on the air-fuel mixture.

What should the downstream O2 sensor voltage be at idle?

The downstream O2 sensor at idle should show a relatively stable voltage, typically around 0.4V to 0.6V, as it monitors the efficiency of the catalytic converter.

What percent should O2 sensors read?

O2 sensors don’t measure in percentages directly but in voltage. However, a functioning sensor typically oscillates, indicating a proper air-fuel ratio near the stoichiometric level (14.7:1 for gasoline).

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.