In current vehicles, the camshaft position sensor is key to ensuring the engine runs smoothly. It won't get as much attention as other components, but without it, your car's engine wouldn't run correctly and might have a hassle starting. In this article, we'll dive into how the camshaft position sensor works, the issues it can face, and how to troubleshoot it when things go wrong.

How Does the Camshaft Position Sensor Work? The Basics

The camshaft function sensor is responsible for sending vital records of the location of the camshaft in your vehicle's Engine Control Unit (ECU). This helps the ECU control key strategies like gasoline injection and ignition timing to ensure the engine is jogging at its first rate.

Generating and Sending Signals

There are two common sorts of camshaft function sensors: magnetic sensors and Hall impact sensors. While each does the same activity—sending statistics to the ECU—they work a little differently.

- Magnetic Sensors: These sensors use a magnetic field to detect changes in the camshaft's function. As the camshaft spins, it creates magnetic pulses, which the sensor picks up and sends as an electrical signal to the ECU.

- Hall Effect Sensors: These sensors use a semiconductor to discover adjustments in magnetic fields. As the camshaft's equipment or magnet passes by the sensor, it generates a virtual signal (either "on" or "off"), telling the ECU where the camshaft is.

What Happens with the Signals?

Once the ECU receives these alerts, it is aware of exactly where the camshaft is and might alter such things as ignition timing and gasoline injection to keep the engine strolling efficaciously. If the signal is off or missing, the engine might have trouble starting or run poorly.

Why the Camshaft Position Sensor is So Important

You might not often think about the camshaft role sensor, but it plays a significant role in your car's performance, fuel economy, and emissions.

- Ignition Timing and Fuel Injection: The sensor tells the ECU precisely when to inject gasoline and fire the spark plugs. By doing these things properly, the engine runs more efficiently, which may lead to higher fuel economy and lower emissions.

- Performance and Power: When the ECU receives accurate records from the camshaft function sensor, it may modify the timing to offer the engine maximum energy and smoothness. That means better acceleration and less vibration.

- Emissions Control: A working sensor enables the engine to burn fuel more completely, reducing harmful gases produced and sent out of the exhaust. That's vital for meeting cutting-edge emissions requirements.

Common Camshaft Position Sensor Problems and How to Spot Them

Like any part, the camshaft position sensor can run into troubles over time. Here are a few issues you might know about and how to restore them:

Symptoms of a Faulty Sensor

- Hard Starting: If the sensor malfunctions, the ECU may not get the right sign, causing the engine to begin or fail to start altogether.

- Engine Stalling or Rough Idling: A failing sensor can cause the engine to run unevenly, with negative acceleration or stalling simultaneously as idling. You may notice the automobile jerking or shaking when you try to pressure.

- Check Engine Light: If your sensor is performing up, the Check Engine Light (CEL) will probably come on. If this happens, it's a great concept to test the OBD-II codes to see if the sensor is the offender.

How to Troubleshoot and Fix the Issues

- Faulty Sensor: If the sensor is broken, the quality answer is to replace it. Make sure the brand-new sensor fits the specifications of the original.

- Dirty Sensor: Sometimes, dirt or oil can accumulate on the sensor, interfering with its function. Cleaning the sensor can restore the trouble. Just make sure to use the proper purifier and avoid damaging the sensor.

- Signal Problems: If the sensor isn't sending a stable signal, use an OBD-II scanner to test for codes and pinpoint whether the problem is the sensor itself or something else, such as wiring or connectors.

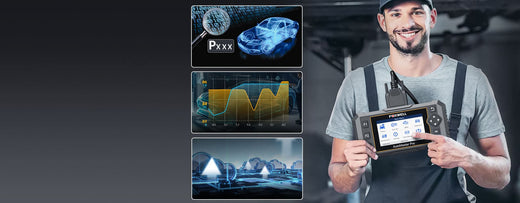

For instance, gear like the Foxwell NT726 allows you to quickly experiment for error codes associated with the camshaft function sensor. It's a reliable diagnostic tool that can help you recognize and fasten troubles earlier than they cause more good-sized engine problems. With capabilities like live records show and O2 sensor trying out, the Foxwell NT726 allows you to get a deeper insight into what's happening along with your vehicle's structures and the camshaft function sensor.

How to Prevent Problems with the Camshaft Position Sensor

To preserve your sensor running properly for years, right here are a few tips:

- Regular Inspections: Periodically check the sensor and its wiring for dirt, corrosion, or loose connections. Clean the area around the sensor to preserve its functioning well.

- Avoid Extreme Conditions: Do not push your car too hard in excessive conditions. Excessive warmth or vibration can cause the sensor to wear down more quickly.

- Use Quality Parts: To update the sensor, buy one that suits the auto's original specs. Cheap, low-first-rate sensors can ultimately motivate extra problems.

Conclusion

The camshaft role sensor can be small; however, it dramatically impacts how your car runs. From ensuring your engine starts up effectively to preserving your emissions, it helps your car carry out at its first rate. By understanding how it works, recognizing the signs of trouble, and acting regularly in preservation, you can keep your automobile running efficiently and avoid highly-priced maintenance.

FAQs

How do I know when my camshaft position sensor needs to be replaced?

If your engine is hard to start, stalls frequently, runs roughly, or the check engine light comes on with error codes related to the camshaft sensor, it’s likely time to inspect or replace the sensor.

What is the difference between a camshaft sensor and a crankshaft sensor?

The camshaft sensor monitors the camshaft’s position to manage fuel injection and valve timing, while the crankshaft sensor tracks the crankshaft’s position to control ignition timing. Both are essential for engine performance, but they serve different functions.

How do you troubleshoot a crankshaft position sensor?

Use a diagnostic tool like the Foxwell NT726 to scan for error codes, inspect the sensor’s wiring and connections for damage, and test the sensor’s signal output with a multimeter to identify issues.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.